Project Overview:

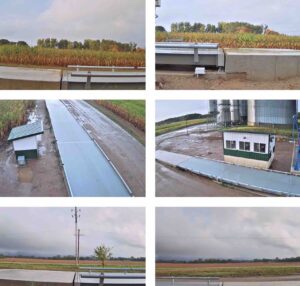

CatchMark was tasked by a customer to devise a network and security solution for their grain elevator. The customer’s primary objective is to streamline operations with minimal on-site staff. Essential aspects include enabling staff to monitor facility activities for security and overseeing truck weights during entry and exit.

Project Duration

The project spanned five months, with the timeline influenced by the concurrent progress of the larger initiative to bring the facility online and updated. Priority was initially given to establishing the network in the office space, while the installation of cameras was deferred to a later stage in the project.

Technology Stack

- Unifi Flex Switch

- Unifi U6 Mesh Access Point

- Unifi Flex Utility Enclosure

- Ubiquiti airMax ManoBeeam Gen2

- Outdoor PoE converter

Project Challenges

The project presented two key challenges for the CatchMark team to address. Firstly, there was a need to find a solution for mounting cameras onto the side of the grain bins while safeguarding them from potential damage caused by ice and snow during winter. To meet this challenge, the team fabricated custom camera protection guards, ensuring the cameras’ safety throughout the year. Secondly, the customer requested a camera installation at the end of a probe used for testing material moisture in trucks, aiming to verify the correct testing locations. To address this requirement, the team designed and fabricated a custom mount that not only fulfilled the customer’s needs but also surpassed their expectations.

Results

CatchMark successfully delivered and implemented the project for the customer, providing tailored solutions that have enabled them to effectively manage and monitor their facility operations. The implemented solutions have empowered the customer to meet their operational objectives, enhancing efficiency and ensuring seamless monitoring of facility activities.